Such increased understanding will contribute to the development of more efficient processes and materials, which serve to reduce negative impact on the environment.

The building of cars with lightweight, high-strength materials and the use of advanced surface technology in the manufacture of engine components can reduce fuel consumption and consequently negative environmental impact. By studying materials science and surface technology using advanced microscopy and surface-analysis techniques, we can develop new functional materials and optimise processes of efficiency.

Our research focuses on materials science and surface technology, with particular focus on metallic materials. We study everything from traditional construction materials (such as steel) to more advanced materials that have been specially designed for specific applications (for example, coated cemented carbide for cutting machining). Understanding the connection between the microstructure of a material, its properties and its resulting performance is the main focus of our research.

In the subject Materials Technology, we offer a two-year Master's Programme in Materials Engineering and Product Development, 120 credits, where we use our advanced surface-analysis instruments and carry out projects in close collaboration with industry.

Steel Research Academy

The Steel Research Academy educates PhD students with the purpose of increasing collaborations and exchange of knowledge between the steel business sector and academia, and to contribute with more research merited co-workers in Swedish companies.

This investment in a constant development within the Swedish steel industry has been financed by Jernkontoret, Region Dalarna, Region Gävleborg, Dalarna University, Sandvikens municipality and collaborative companies.

Collaborations have been established with SSAB, Sandvik, Outokumpu, Voelstalpine and Triple-Steelix.

It's a mix of leading Swedish steel manufactures and producers, along with the innovation & evolution agency Triple Steelix.

The PhD students are a vital link between the businesses and the universities. Through their research new insights and collaborations are born and developed.

Steel Forming and Surface Engineering

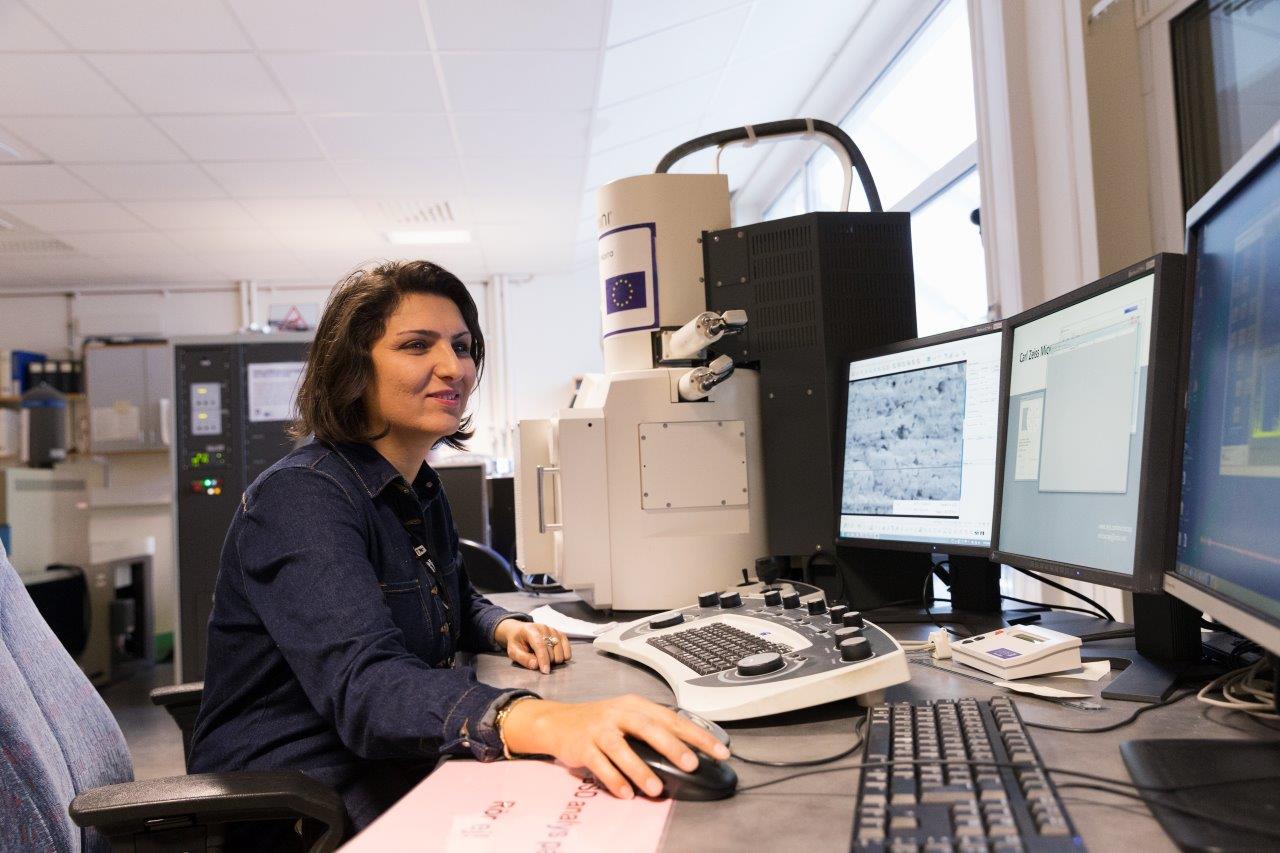

Within the fields of metal working and metal forming, our research focuses on the development of physically based models of the microstructural evolution of carbon and stainless steels during plastic deformation. Mechanical characterization using, for example, thermo-mechanical compression testing as well as microstructural characterization using high resolution scanning electron microscopy in combination with electron backscatter electron diffraction (EBSD) are used to obtain in-put parameters for the modelling. The work is performed in close collaboration with the Swedish steel industry.

Within the fields of tribology and surface engineering, we concentrate on the mechanisms of friction and wear and the way in which materials design and surface engineering can be applied to obtain improved performance in different types of applications such as metal forming, metal cutting and rock drilling.

The research is diversified, including advanced methods for mechanical and tribological testing, state-of-the art techniques for microscopy and surface analysis, friction and wear modelling and surface engineering. Research is conducted in close collaboration with both Swedish industry and other institutes of higher education in Sweden.

Research Profile: Steel Forming and Surface Engineering

Laboratory Facilities

Equipment for Preparation of Metallographic Samples

Automatic precision cut-off machine, Struers Accutom-50

Automatic precision cut-off machine, Struers Accutom-50- Automatic metallurgical polishing machine, Struers TegraPol-15

- Automatic hot mounting press, Struers CitoPress-1

- Automatic electrolytic polishing system, Struers LectroPol-5

- Ion beam milling system, Leica EM TIC 3x

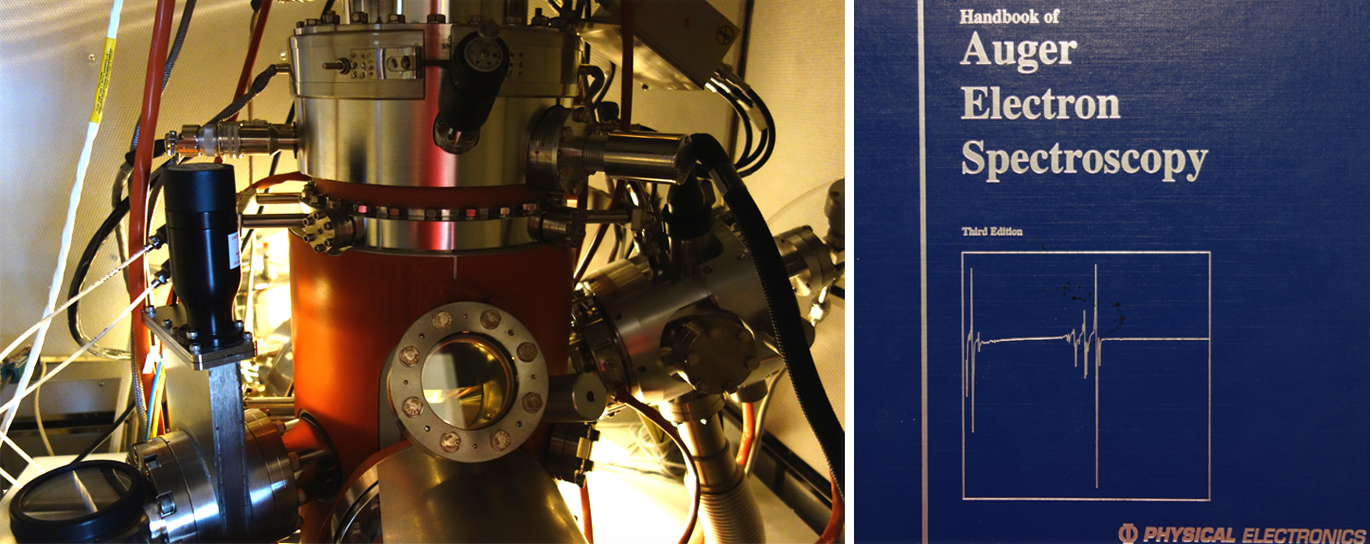

Instruments for Advanced Microscopy and Surface Analysis

- Light optical microscope, LEICA DMRME

- Image analysis system, Q500MC

- High resolution scanning electron microscopy (HRSEM), Zeiss Ultra 55 FEG-SEM

- Energy dispersive X-ray analysis system (EDS), INCA Energy 450

- Electron backscatter diffraction system (EBSD), Ultrafast Nordlys F400

- Secondary ion mass spectrometry instrument (ToF-SIMS), PHI 2100 TRIFT II

- Auger electron spectroscopy instrument (AES), PHI 700Xi Auger Nanoprobe

- Fourier transform infrared spectrometer (FTIR), Perkin Elmer Spectrum I

- 3D optical surface profiling system, Veeco Instruments WYKO NT 9100

Equipment for Mechanical Testing (Macro)

- Tensile testing machine, Shimatzu

- Charpy impact tester, Charpy-V 300J

- Hardness testers (Brinell, Rockwell, Vickers)

- Scratch tester, CSM Revetest

Equipment for Mechanical Testing (Micro)

- Micro hardness tester, Matsuzawa MXT50

- Micro combi tester (open platform, indentation and scratch testing), CSM Instruments

- In-situ microtest stage for SEM, Gatan Microtest 5 kN

Equipment for Tribological Testing

- HT tribometer, CSM Instruments

- Macro scratch tester (Revetest), CSM Instruments

- Micro combi tester (open platform, indentation and scratch testing), CSM Instruments

- Micro abrasion tester, Gatan

Furnaces, Temperature and Climate Chambers

- High-temperature furnaces, Nabertherm

- Temperature and climate test chambers, WEISS

Collaboration with Companies

The Materials Technology Department at Dalarna University has a wealth of experience in terms of teaching and applied research within this multi-disciplinary, fascinating field. The professional competence of staff covers a range of disciplines, and the access staff and students have to modern equipment allows for the characterisation of the structures, compositions and properties of different materials.